EVs are thriving as a feasible commuting alternative to alleviate environmental problems by reducing dependence on fossil fuels. And the rising demand for EVs necessitates automotive players to consider multiple aspects influencing their effectiveness and performance, ultimately experienced by the users. This resulted in numerous research pivoted by manufacturers and OEMs focused on boosting electric vehicle (EV) performance for the upcoming decades. One such outcome is the Battery Management Solution (BMS), which helps monitor the battery performance and controls associated parameters, ensuring competent and safer EV offerings.

The Global Electric Vehicle Battery Management Systems Market was 1.42 billion US$ in 2021. The market is expected to grow at a CAGR of 17.2% from 2022 to 2027 and is estimated to reach US$ 5.67 billion by 2027.

These numbers merely cement the fact that BMS is nothing but the nerve centre for electric vehicles, playing a critical role in managing the battery’s performance. This blog discusses the Battery Management System’s (BMS) significant contribution to Electric Vehicles (EVs).

What is a Battery Management System for Electric Vehicles?

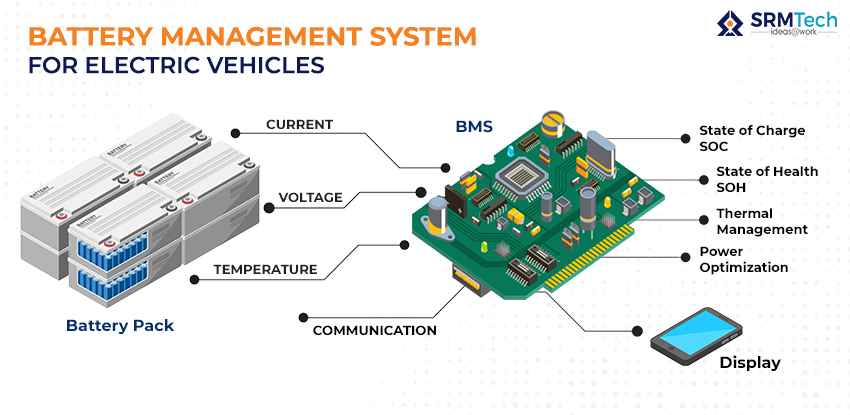

A Battery Management System, commonly known as BMS, is an electronic unit that plays a vital role in monitoring and controlling the performance of EV batteries. It controls voltage, temperature, and state of charge, which are critical parameters for the safe operation of batteries commonly used in EVs.

Why do we need a Battery Management System in Electric vehicles?

Lithium-ion batteries are the most favoured category among the batteries used in electric vehicles, owing to high power density, low self-discharge, and reasonably low cost. Nevertheless, along with the advantages, many safety risks are involved in making an electric vehicle with a lithium battery. Because, under unusual conditions, lithium-ion batteries may fail and even result in fire due to various reasons like overcharging/over-discharging, thermal runaway, age and wear. This pushes Automakers & OEMs to deploy effective Battery Management Solutions (BMS) to ensure EV batteries are under optimal safety limits to provide safer e-mobility. The section below explains what and how the BMS addresses EV battery operations.

In an electric vehicle, a battery amalgamates several modules, each a collection of individual cells. It is challenging to monitor battery pack performance since each cell in each module tends to charge and discharge at different rates. Also, each cell functions differently due to temperature, health status, and energy. Therefore, each battery cell must be independently observed for safer and more efficient operation. This is where BMS comes into play – it performs routine checks on the parameters, and if it detects any anomalies, it takes immediate corrective measures. This inspection ensures the battery’s safe and reliable operation, producing an efficient and safe electric vehicle for consumers.

Types of Battery Management Systems in Electric Vehicles

There are two types of Battery Management Systems – Centralized BMS and Distributed BMS.

A centralized BMS has one control unit managing all cells, which is cost-effective; however, it exposes the entire system to total failure in case of control unit malfunction. On the contrary, multiple control units are commissioned to enhance system resilience in a distributed BMS. Now, this comes with increased complexities and costs. Automotive brands choose the BMS system that best aligns with their needs and requirements, where price leans towards a centralized BMS and reliability goes for a distributed BMS.

Functions of Battery Management Systems in Electric Vehicles

The Battery Management System (BMS) plays several critical functions in electric vehicles, as in the following pointers.

Cell Monitoring:

The BMS fetches real-time data on fundamental battery parameters like voltage, temperature, and current. With these metrics, BMS closely monitors important performance parameters like State of Charge (SoC), denoting the amount of charge remaining out of the EV battery’s maximum capacity and State of Health (SoH), showing the overall status of battery pack health. SoC monitoring helps EV customers asses their disposable driving range and plan their charging station stops without worrying much about range anxiety. With SoH monitoring, EV manufacturers could practically assist their customers by providing heads-up on preventive maintenance, retaining healthy battery conditions and prolonged performance.

Thermal Management:

Electric Vehicle Batteries are sensitive to temperature variations, influencing their performance and lifespan. On this note, the BMS carefully regulates the thermal state of the battery through constant monitoring and control of battery temperature values to maintain optimal operation. For instance, this can involve utilizing heating-cooling mechanisms to keep the batteries within ideal temperatures to maximise their performance and lifespan.

Cell Balancing:

BMS includes a cell balancing process to make the energy cells perform uniformly. At a fully charged state, it equalizes the voltage and state of charge among the cells through two distinctive methods: active balancing – transferring energy from overcharged to undercharged and passive balancing – excess energy is discharged through dissipative bypass mechanisms. Hence, no one cell gets overcharged or under-charged. Cell balancing increases the efficiency and longevity of the battery pack in an electric vehicle.

Battery Optimization:

The BMS vigilantly monitors the multiple parameters of the battery packs since battery cells may lose their integrity as they naturally deteriorate over time. It has built-in protections for overvoltage, undervoltage, overcurrent, thermal management, and external overcharge/discharge incidents. In case of anomalies, the system will automatically regulate the pre-defined protection process, like optimized low voltage charging for damaged cells & balancing voltage variations due to oxidation to keep the battery performance optimal.

This makes the BMS an essential component as it ensures the functioning, reliability, and safety of batteries used in electric vehicles, thereby enhancing the growth of eco-friendly transport for your potential consumers.

Benefits of using a Battery Management System for EVs:

BMS has several significant advantages for electric vehicles. These benefits include:

Performance Optimization:

BMS helps derive the maximum performance of the battery packs to extend the driving range and battery longevity through automated mechanisms to resolve anomalies and malfunctions pertaining to the battery.

Safety and Reliability:

BMS has complete monitoring and safety mechanisms for overcharging, draining, and temperature abnormalities. This ensures the safety and durability of a battery, thus minimising accidents, or failures for EV buyers.

Real-time Data and Diagnostics:

BMS observes batteries in real time, records data for logs on battery health, and identifies malfunctions. This helps OEMs schedule proactive maintenance to rectify issues and significantly enhance customer satisfaction.

Current trends in BMS

Automotive OEMs consistently test new waters to evolve their BMS capabilities and strengthen their automotive offerings. Some notable developments in the BMS space include:

Intelligent BMS:

By employing advanced algorithms and machine learning techniques, BMS can optimize battery performance according to patterns of batteries’ utilization, environment conditions, and other dynamic scenarios. This advancement is valuable for automakers by reducing warranty claims and enhancing their reputation for reliability.

External Communication:

Wireless communication protocols can be seen increasingly leveraged with BMS, enabling them to have system enhancements at speed through Over-the-Air (OTA) updates. Meanwhile, with timely updates, Automotive OEMs can ensure their BMS functionality and performance are intact.

Advanced Predictive Algorithms:

Battery Management Systems in electric vehicles are being integrated with advanced predictive maintenance systems. These algorithms rely on real-time data to anticipate when battery components may require repair or replacement, reducing customer maintenance costs, improving vehicle reliability, and enhancing brand reputation.

As we can see, BMS capabilities are progressing by leaps and bounds with new technological innovations and it is time for automotive OEMs to keep pace with this evolution.

Talk to us if you are looking for Battery Management Solutions to drive your e-mobility initiatives forward. SRM Technologies has comprehensive expertise in automotive embedded and digital engineering, helping automotive players ensure effective utilization, battery life and overall performance.