Supply chains are naturally intricate networks involving various stakeholders, processes, and global operations. However, despite their complexity, supply chains exhibit remarkable adaptability to changing conditions, thriving amidst challenges such as labour shortages and evolving consumer preferences.

To navigate these hurdles effectively, businesses are increasingly turning to Supply Chain Orchestration (SCO), a strategic solution that optimizes supply chain management by integrating data, technology, and human expertise. In this blog, let’s explore the concept of SCO, the crucial role of technology, and the key components essential for a successful SCO strategy.

What is Supply Chain Orchestration?

Supply Chain Orchestration (SCO) is a strategic methodology for efficiently managing and optimizing the supply chain operations to ensure competitive delivery of products and services to customers. It encompasses the seamless coordination of end-to-end (E2E) supply chain elements – from sourcing raw materials to final product delivery, including production, inventory management, transportation, and logistics operations. SCO enables accurate customer demand forecasting and fosters global supplier collaboration so companies can streamline product flow, drive efficiency gains, and reduce operational costs effectively.

Difference Between Logistics Orchestration and Supply Chain Orchestration

Before pitching deeper into the importance of Supply Chain Orchestration, let’s briefly differentiate between logistics orchestration and supply chain orchestration.

| Aspect | Logistics Orchestration | Supply Chain Orchestration |

|---|---|---|

| Scope | Logistics Orchestration optimizes only the individual logistics functions, such as transportation and warehousing. | Supply Chain Orchestration encompasses strategic coordination of E2E supply chain activities, including logistics, procurement, manufacturing, and distribution. |

| Objective | It aims to streamline the movement and storage of goods within a specific supply chain segment. | It seeks to enhance E2E supply chain efficiency, responsiveness, and competitiveness by integrating and optimizing all processes. |

| Coordination | Coordinates logistics activities within a specific function or department. | Coordinates activities across multiple functions and stakeholders throughout the entire supply chain ecosystem. |

The Importance of Supply Chain Orchestration

Supply Chain Orchestration plays a vital role in ensuring the success of organizations, particularly during times of uncertainty and disruption like the Covid-19 pandemic. These unprecedented challenges have provided Supply Chain Orchestration with a unique opportunity to prove its worth, as companies grappled with maintaining the continuity of end-to-end supply chains for critical products, optimizing resource allocation, and swiftly addressing disruptions. Research findings from EY also confirm that the pandemic intensified existing supply chain challenges and emphasized the crucial need for visibility, resilience, and digitalization.

Now, let us further explore why a supply chain orchestration platform is essential.

Visibility & Agility in Supply Chains

Supply Chain Orchestration fosters secure, transparent, and precise collaboration across all the nodes of the supply chain ecosystem, from product producers to end customers. It detects potential issues and forecasts obstacles by providing a detailed view of the supply chain. This heightened transparency significantly bolsters agility, enabling businesses to respond promptly and maintain uninterrupted operations. Increased visibility not only aids in averting minor issues, thus enhancing customer service but also expedites the resolution of more significant issues as they arise.

According to KPMG’s report, nearly two-thirds of global business leaders are accenting the need for increased visibility into their supply chains to sustain operational stability.

Efficiency & Financial Growth

Implementing efficient supply chain orchestration leads to both the optimization of operations and the financial performance improvement of the business. By utilizing data-driven insights, you can identify potential opportunities for improvement, reduce costs, and increase productivity. Also, automating tasks and streamlining workflows significantly minimize operational expenses, positively impacting the bottom line while ensuring optimal resource utilization.

Automated Compliance Management

Automated management for efficient, resilient compliance ensures businesses adhere to regulations by proactively monitoring and enforcing compliance measures, maintaining operational integrity, and fostering customer trust. This approach enhances efficiency and safeguards against potential disruptions, ensuring sustained compliance. Additionally, as regulations evolve, automated management ensures businesses remain adaptable, minimizing the impact of regulatory changes and bolstering resilience, ultimately attaining a seamless and compliant supply chain operation along with all external entities involved.

For example, in pharmaceutical distribution, automated systems monitor temperature controls during transportation to comply with strict regulatory requirements for storing and transporting temperature-sensitive medications, ensuring their efficacy and patient safety.

The Role of Technology in Driving Supply Chain Orchestration Innovation

In the section below, we shall discuss how the supply chain orchestration platform is driven by employing different technologies.

Automation and Robotics

Organizations are adopting automation and robotics to enhance their supply chain operations in response to the growing demand for efficiency. Robotic arms play a crucial role in warehouse operations by efficiently handling tasks such as picking and packing SKUs while ensuring precision and speed in order assembly. Additionally, autonomous mobile robots (AMRs) navigate through warehouse aisles, retrieving items and delivering them to human workers for packing or directly to shipping stations, thus streamlining the order fulfilment process. Moreover, Collaborative robots (cobots) work seamlessly alongside human operators, assisting with sorting, labeling, and palletizing tasks.

As an industry leader, Amazon exemplifies the power of automation and robotics in supply chain orchestration, with hundreds of thousands of robots optimizing picking and packing processes across its vast network of warehouses.

Blockchain Technology

Blockchain technology provides a decentralized and tamper-proof system that improves the transparency and traceability of the supply chain. Envision a way whereby every transaction is securely logged and verified across nodes, providing unmatched visibility of product origin and authenticity – that’s how blockchain technology adds value to supply chain modernization.

Walmart, the front-runner in the global adoption of blockchain technology, tracks the processing of some food products by utilizing this system and verifies food safety and regulatory compliance.

Also, in another scenario, Walmart resolved payment management and data discrepancies in its Canadian supply chain by implementing a blockchain solution co-developed with DLT Labs. This technology digitizes and automates the payment process, providing transparency and accuracy for transactions between Walmart and its third-party logistics partners, thereby reducing disputes and ensuring timely payments.

AI and Machine Learning

AI and Machine Learning (ML) techniques are increasingly used to optimize supply chain operations. Imagine using predictive analytics to forecast customer demand better for production planning, optimize delivery routes, and control inventory levels. Besides, incorporating AI and Machine Learning into Supply Chain Orchestration facilitates the creation of supply chain digital twins, a digital replica of your assets enabling organizations to simulate and optimize E2E supply chain processes for enhanced efficiency and customer satisfaction.

Companies such as UPS and FedEx use machine learning algorithms to analyze massive quantities of data and optimize their distribution networks, lowering fuel usage and increasing delivery efficiency. AI and machine learning integrated Supply Chain Orchestration enables organizations to make data-driven supply chain decisions, promote operational efficiency, and provide exceptional consumer experiences.

Warehouse Management System (WMS)

A Warehouse Management System (WMS) is a software application that enables organizations to manage and optimize their warehouse operations efficiently by providing functional stakeholders with real-time visibility into inventory levels, order fulfilment processes, and warehouse layout planning. With a WMS, organizations can automate processes, optimize storage space, and improve accuracy, reducing costs and enhancing customer service. Implementing a WMS empowers organizations to streamline warehouse operations and drive efficiencies throughout the supply chain.

Transport Management System (TMS)

A Transport Management System (TMS) is a pivotal software suite that adds value to the supply chain orchestration by managing the complete movement of goods from the point of origin to the last-mile delivery. It enables supply chain teams to achieve route optimization, consolidate shipments, and find the most cost-effective carriers so transit inefficiencies are minimized and transportation is cost-efficient.

Global brands like Amazon utilize Transportation Management Systems (TMS) to synchronize their complex end-to-end supply chains. TMS enables them to streamline route planning for suppliers, distribution centers, and warehouses. TMS enhances agility and responsiveness by integrating real-time analytics, swiftly addressing market changes and customer demands.

Gartner reports that about 83% of businesses now acknowledge the crucial role of supply chain digitalization in enhancing the customer experience.

By embracing these technological advancements and weaving them into their supply chain strategy, organizations can unveil fresh visibility, efficiency, and customer satisfaction levels.

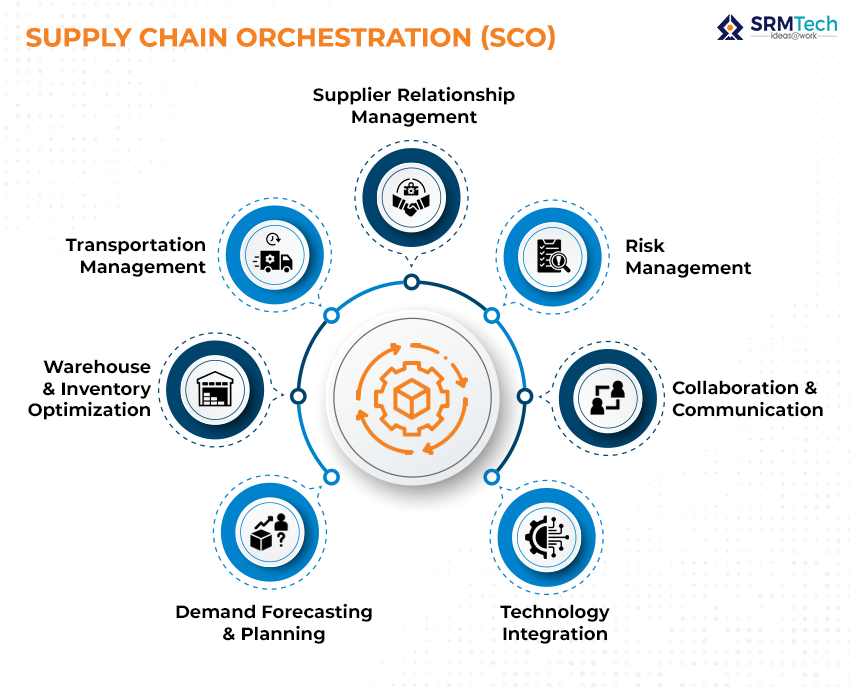

Key Components of a Successful Supply Chain Orchestration Strategy

Now that we understand the concept of supply chain orchestration, its advantages, and the associated technologies, let’s look at how you can craft an effective Supply Chain Orchestration (SCO) strategy to excel in today’s competitive environment.

- Strive to gain visibility into every aspect of your supply chain to empower informed decisions, prompt incident resolution, and monitor inventory, transportation, production, and demand.

- Foster effective communication and collaboration among supply chain partners to share real-time data, insights, and plans, ensuring operational readiness to meet business demands.

- Optimize processes by embracing innovative technologies like AI, IoT, and blockchain to automate tasks, predict trends, and enhance efficiency across your supply chain.

- Efficiently manage inventory by utilizing demand forecasting and optimization techniques to maintain ideal levels while minimizing costs and avoiding stockouts.

- Tailor supply chain processes to deliver superior service and personalized experiences by understanding customer preferences and behaviors.

- Build an agile, flexible end-to-end supply chain ecosystem to navigate market shifts by reconfiguring processes, rerouting shipments, and adjusting production schedules swiftly.

- Identify and mitigate risks by assessing vulnerabilities and establishing contingency plans, minimizing disruptions from natural disasters or unprecedented failures.

- Drive operational excellence by continuously monitoring, evaluating, and improving supply chain processes, seizing optimization opportunities to maintain competitiveness.

By integrating these components into your Supply Chain Orchestration strategy, you can effectively enhance competitiveness, mitigate risks, and deliver value to your customers. Remember that Supply Chain Orchestration is not a one-time initiative but an ongoing effort to adapt, optimize, and exceed customer expectations, achieving long-term success in your supply chain operations.

Industry level Supply Chain Orchestration examples

Retail

Retailers can optimize inventory management and ensure the timely availability of SKUs in their respective mediums using supply chain orchestration. Through this process, they synchronize inventory across multiple channels, manage returns efficiently, and offer seamless omnichannel experiences. By leveraging supply chain orchestration, retailers could provide customers with a smooth, hassle-free shopping experience tailored to their needs.

Manufacturing

Manufacturing industries can streamline production processes and minimize lead times through supply chain orchestration. This involves synchronizing production schedules with raw materials and OEM suppliers, optimizing logistics, and reducing production downtime. With supply chain orchestration, manufacturers could deliver high-quality products efficiently, ensuring customer satisfaction and brand trust with every purchase.

Healthcare

In the healthcare sector, supply chain orchestration plays a vital role in ensuring the timely delivery of medical supplies and pharmaceuticals. Healthcare providers can manage inventory levels, track critical supplies, and respond effectively to healthcare crises such as pandemics. By leveraging supply chain orchestration, healthcare institutions could provide heightened priority toward patients’ well-being, ensuring they have the necessary resources on time to deliver ideal care and diagnosis.

Food and Beverage

Food and beverage companies can manage complex distribution networks and ensure food safety compliance with the help of supply chain orchestration. This involves tracking ingredients from farm to table, optimizing transportation routes, and minimizing waste. By utilizing E2E supply chain solutions, these companies could provide high-quality, fresh, safe food products across their widespread market geographies.

Electronics

Electronics manufacturers can leverage supply chain orchestration to navigate global supply chains and effectively adapt to changing consumer demands by optimizing inventory, streamlining production processes, and prioritizing customer satisfaction. During the recent global semiconductor crisis, supply chain orchestration played a crucial role in mitigating disruptions by enabling manufacturers to identify alternative sourcing options, adjust production schedules, and maintain communication with stakeholders. This agile approach helped minimize the impact of the crisis and ensured continued operations.

In today’s era of technological advancement, leveraging Supply Chain Orchestration has become considerably easier, resulting in the timely delivery of products or services to customers. With everything interconnected, businesses can utilize various tools and technologies to streamline supply chain operations, elevating efficiency and performance to new levels.

At SRM Tech, we specialize in developing and implementing tailored end-to-end supply chain solutions, driving business growth and fostering innovation. With advanced digital technologies and data-driven insights, we enable enterprises to obtain comprehensive visibility over their supply chain and a competitive edge in their business landscape.

Reach out to us to explore how our supply chain digitalization offerings can help you achieve exceptional operational excellence, cost-effectiveness, and exceed customer satisfaction.